Production process of HSS sections

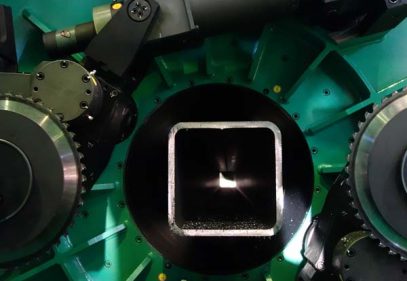

The transformation of steel strip into hollow structural sections(HSS) in the cold rolling method is done in severaldifferent ways, and this article mentions one of the most up-to-date and optimal production methods. In this method, the flat steel sheet is continuously formed along the longitudinal axis during a cold rolling process to become a tube with a round cross-section. It is done by moving the sheet through a set of rollers. The edges of the sheet are placed adjacent to each other andheated by high-frequency induction welding or contact welding and the edges sink into each other as a result of weldingto form a continuous longitudinal weld without the need to add filler metal(electrode) to be formed. Then the weld seamis bent and finally it is converted into round, square or rectangular sized sections by passing through a series of sizingrollers during another cold rolling process.