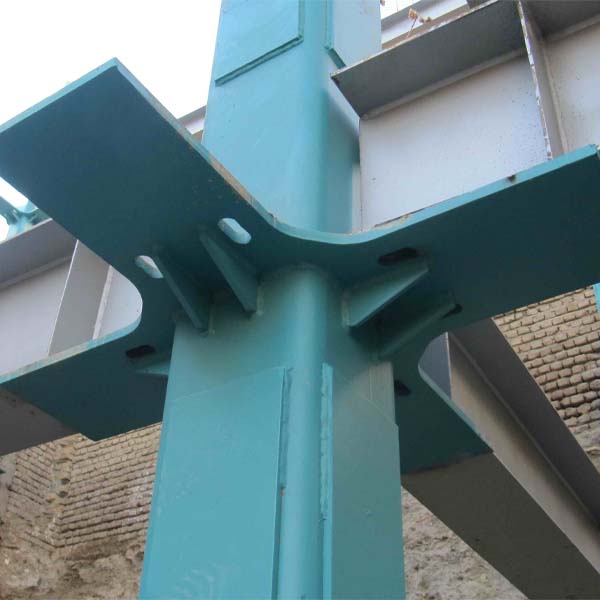

HSS stands for Hollow Structural Section that is a metal profile with a hollow crpss section. Round, square and rectangular shapes of HSS profile have many applications in various indusries.

HSS profiles are being manufactured in 2 methods:

- Tranditional production method ( welding and cutting by manpower)

- Modern industrial production metho ( by fully automated and integrated machinery)

HSS has many various applications in defferent industries such as Construction. Oil and Gas, municipal Engineering and many other industries.