Cold-rolled Non-alloy steel pipe with seam welding - Structural, Industrial and Water supply applications

Cold-rolled Non-alloy steel pipe with seam welding - Structural, Industrial and Water supply applications

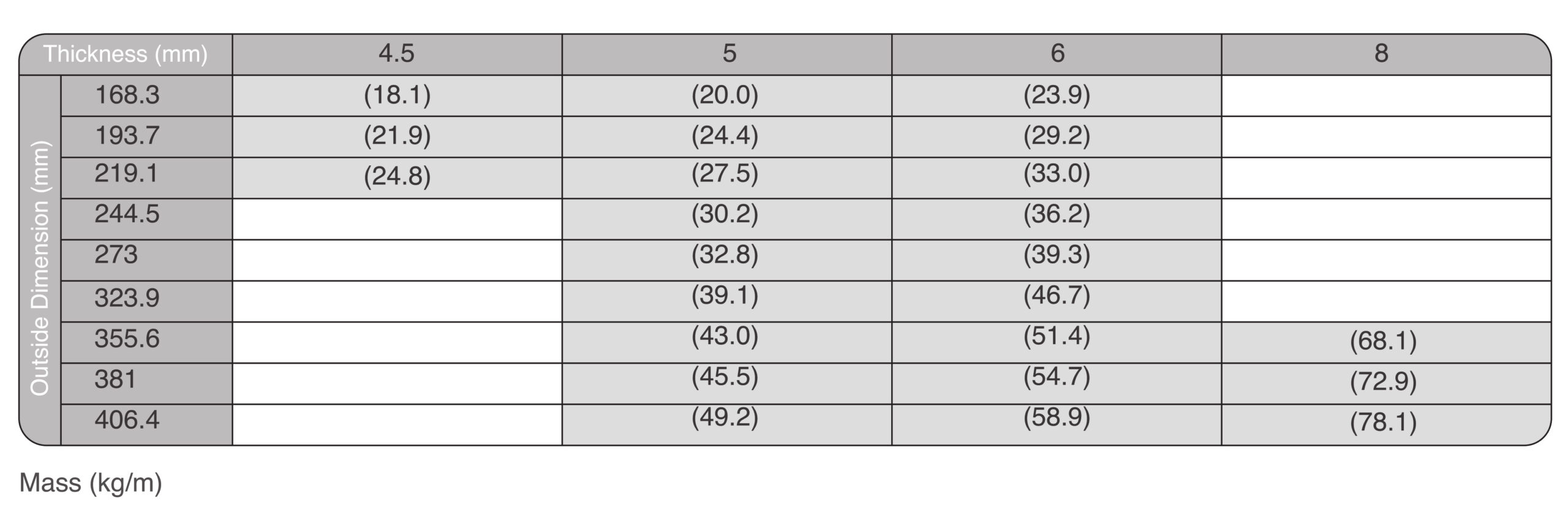

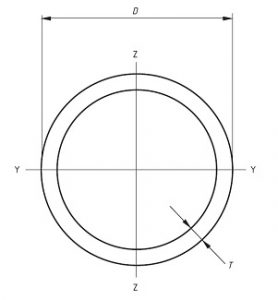

Water supply pipe is a steel profile with round section, which is one of the most essential components of water distribution and transmission networks, which is produced in different diameters and thicknesses, and its main purpose is to transfer water from the source or treatment center to the consumers. These pipe can also be used to transfer other fluids. Industrial steel pipes are ready to be used for water supply purposes after making changes such as removing the internal welding beads and beveling the ends of the pipe and conducting hydrostatic tests.

water supply pipes can be used for water supply after passing destructive and non-destructive tests based on EN10217 and AWWA standards.

Effective performance against corrosion, high resistance and strength, pressure tolerance, long life and recyclability, made steel pipes the most suitable method for transporting drinking water and municipal wastewater.

In the method of producing water pipes based on the EN10217 standard, the coil sheet is slowly bent by passing through multiple rollers and becomes circular, when the two ends of the sheet are welded to each other by ERW welding and produce a round and integrated pipe. Then its internal and external beads are removed; Therefore, these pipes are also called seam pipe and welded steel pipe. These pipes are tested by hydrostatic tests in order to check the welding seam in terms of leakage at certain pressures.

In seamless pipe production method, welding bead must be removed from the outer and inner part of the pipe during production, so that we have a pipe without welding bead, with a round, hollow section and free of any kind of damage.

After the continuous production of seamless pipe, in the cutting stage, the pipe is cut to the required lengths, which will be done by a cutting machine (Cut-Off) with high precision, we will have a pipe without welding bead. After performing the required tests and Beveling according to international standards, the manufactured pipes are ready to be presented for operations.

The lower production cost compared to Mannesmann pipes and high welding resistance of ERW pipes have increased the demand of various industries, including water supply and wastewater, oil and gas, petrochemical, etc.

EN standards or European standards (European Norms) are compiled, revised and developed standards by the European standardization organization CEN (Comité Européen de Normalisation). The EN 10217-1 standard is dedicated to carbon steel welded pipes, which are used to transport fluids under pressure or without pressure. Among the applications of these pipes, we can mention the transportation of gases, liquids, and etc.

AWWA stands for American Water Work Association. AWWA is a non-profit organization founded in 1881. AWWA works with about 50,000 members and aims to improve public health, protect the environment, strengthen the economy and increase our quality of life.

All material and intellectual rights of this work are reserved for Athena Foulad Gostar Company

User Comments