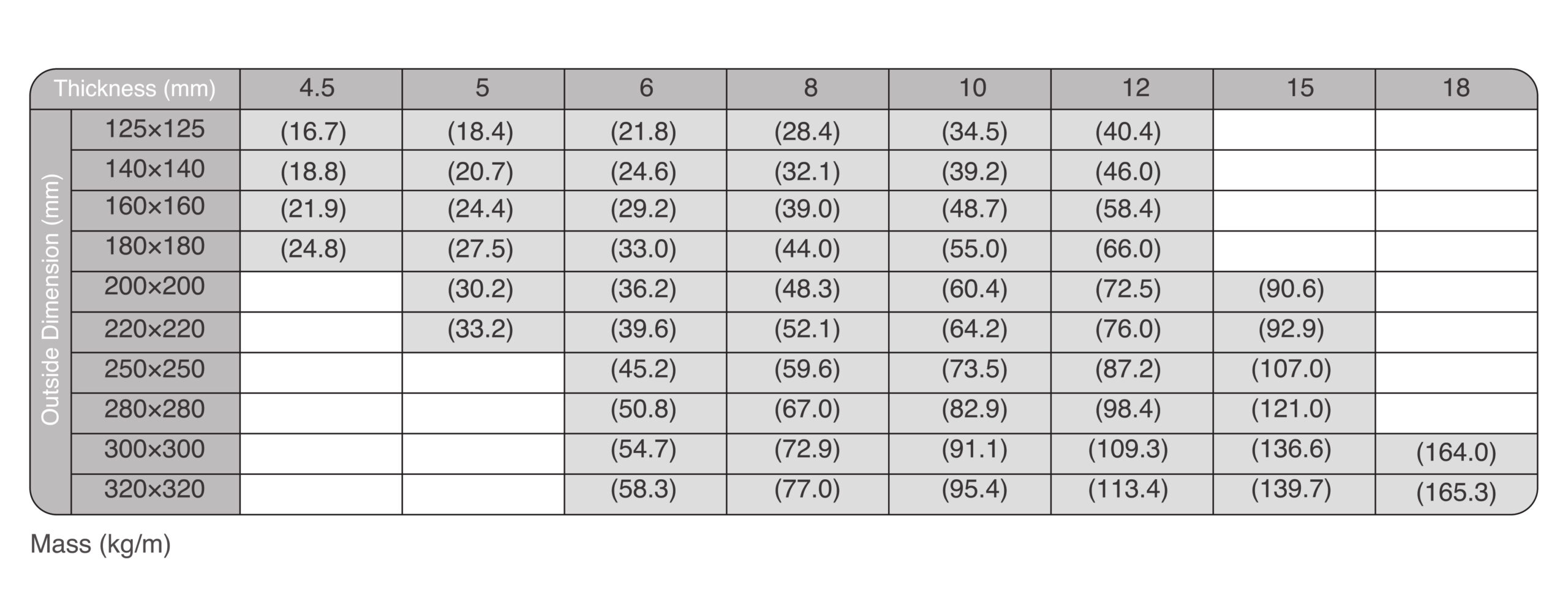

Hollow sections of non-alloy steel with welded joints and cold rolling have structural applications

Hollow sections of non-alloy steel with welded joints and cold rolling have structural applications

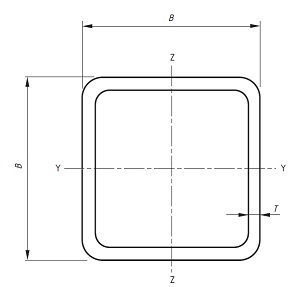

Hollow structural sections (HSS) are welded, high-strength steel tubes that act as a load-bearing part in metal structures. These sections are among the most diverse and efficient structural profiles that have multiple applications in industry and construction.

Steel square tubes are used as metal columns and braces in the construction industry, which has many advantages for steel structures. Also, these sections have many uses for the construction of industrial machine chassis, heavy vehicle chassis, smart parking lots, pedestrian bridges and car bridges, airport structures, etc.

These sections are among the most diverse and efficient structural profiles that have multiple applications in industry and construction.

All material and intellectual rights of this work are reserved for Athena Foulad Gostar Company

User Comments