Hollow sections of non-alloy steel with welded joints and cold rolling have structural applications

Hollow sections of non-alloy steel with welded joints and cold rolling have structural applications

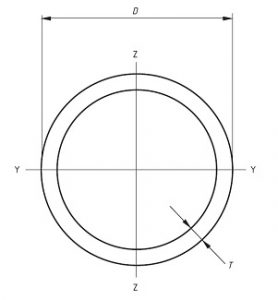

Industrial steel pipes refer to cylindrical structures made of steel that are utilized in various industries. These pipes are constructed from metallic alloys including iron and other metals such as aluminum, manganese, etc., offering greater strength and durability compared to iron pipes.

Due to their longevity, high resistance, and effective performance against corrosion, these pipes are widely used in applications such as water, gas, and oil transmission, making them the most commonly used steel sections. Moreover, these pipes are also utilized in the construction of steel structures including warehouses, buildings, bridges, stadiums, playgrounds, etc.

FGA Company produces steel pipes by electric resistance welding (ERW) method, using the advanced Norwegian EFD Weldac 1500 device. by relying on the localized technology, it can remove internal and external welding beads.

Direct welding and non-use of secondary material increases the strength and durability of this pipe compared to similar pipes. Higher accuracy and speed and lower tolerance in diameter and thickness in the ERW welding method leads to the production of steel pipes in a higher volume and also reduces production costs. The smooth and uniform welding seam that reduces friction and stable quality is also one of the many advantages of ERW welded steel pipes.

All material and intellectual rights of this work are reserved for Athena Foulad Gostar Company

User Comments