Water and Energy Industries

Water and energy industries

water and energy industries are key areas in the economy of any country, which is related to the production, distribution and management of water and electricity resources. This industry has an important influence on the process of economic and social development and plays a large role in providing human and industrial needs for water and energy. Water supply pipe, casing pipe and structural pipe have many applications in these industries.

The power sector includes the production, transmission, and distribution of electrical energy (electricity), which includes power plants, transmission and distribution networks, and activities related to the exploitation of natural sources such as water, oil, gas, solar, and wind energy.

Application of steel HSS tubes in water and energy industries

Steel profiles and pipes are used in water and energy industries as one of the main and vital construction infrastructures. These sections are used in many sectors of water and energy industries due to their special features, including strength, flexibility, resistance to pressure and heat, and long life. Below we mentioned some of the main applications of steel pipes and profiles in these industries:

- Water and wastewater piping: Steel pipes are widely used in irrigation networks, wastewater treatment networks, drinking water transmission pipes, and urban wastewater pipes. Due to their high resistance to pressure, heat, corrosion and erosion, these pipes are suitable for transporting water and wastewater in different conditions.

- Gas piping: One of the main choices for transporting gases is steel HSS pipes. These pipes are used to transport natural gases and industrial gases, including liquid gases and compressed gases.

- Power plant buildings: Steel pipes are used to transport water in the form of refrigeration, steam and cooling water in power plants.

- Support and stabilization structures: steel sections are used in support structures, soil stabilization, and infrastructure development in water and power industries. These profiles are used in the construction of columns, towers and support parts.

- Hydraulic and hydrodynamic facilities and projects: In hydraulic projects such as dam construction, steel pipes are used to transfer water to meet agricultural and urban needs.

- Marine facilities such as oil and gas pipes and plates: steel HSS pipes are used as the main lines for transporting fuel and chemicals in marine oil and gas facilities. Generally steel pipes and sections are especially important in water and energy industries due to their strength, resistance and stability, and they are widely used in the construction of structures and equipment related to these industries.

Water supply pipes

Water supply pipes, steel profiles with a round section, are one of the most essential components of water distribution and transmission networks, which are produced in different diameters and thicknesses, and their main purpose is to transfer water from the source or treatment center to consumers. These pipes can also be used to transport other fluids. Industrial steel pipes are ready to be used for water supply after making changes such as removing the internal bead and beveling the two ends of the pipe, as well as performing hydrostatic tests.

Steel pipes are the most suitable method for transporting drinking water and waste water due to their effective performance against corrosion, high strength and resistance, high pressure tolerance and longevity, and recycling capability.

History of water supply pipes

The supply and transfer of drinking and irrigation water and wastewater systems has been one of the most important logistical challenges since the beginning of human civilization for use of drinking water and sanitary purposes, as well as preventing the spread of various diseases and floods. Archaeologists discovered the first copper water pipes around 4000-3000 BC around the Indus River in India. Also, pipes made of clay, which were used around 2500 BC, were discovered in Egypt. These pipes helped a lot to transfer water from the Nile River and irrigate agricultural lands and provide running water.

Around 1000 BC, the ancient Greeks used burnt clay, hollow stones and sometimes bronze as underground clay pipes for sanitation and water supply. Soon after, the Roman Empire developed complex ancient plumbing systems with aqueducts, underground sewers, and bronze plumbing systems.

In addition, around 500 BC, the Chinese used crude bamboo pipes to transport gas that penetrated the earth’s surface and to boil seawater to obtain drinking water. After the fall of the Roman and Greek empires, plumbing technology was discontinued for several decades. During this period, the lack of sanitary water and sewage systems caused many health problems and diseases such as bubonic plague, typhoid fever and dysentery.

In the 16th century, with the industrial revolution and settlement of people in the cities, the first water supply systems appeared in England and Germany, and in the early 1800s, most of the big cities in Europe and the United States used steel pipes for the water supply system. The early 1900s saw the rise of indoor plumbing and running water around the world. In the early fifties of the 20th century, the first polyvinyl chloride (PVC) pipes were used in the United States of America due to the limitations of using steel. After the 1950s, the use of steel pipes for water and sewage applications made significant progress due to their affordability, durability, strength, and corrosion resistance.

With the industrial revolution and the settlement of people in the cities, in the 16th century, the first water supply systems appeared in England and Germany, and in the early 1800s, most of the big cities in Europe and the United States used steel pipes for the water supply system in the cities. In the early 1900s indoor plumbing increased worldwide. In the early 1950s, due to the limitations of using steel, the first polyvinyl chloride (PVC) pipes were used in the United States of America. After the 1950s, the use of steel pipes for water and sewer applications made great progress due to their affordability, durability, strength, and corrosion resistance.

Foulad Gostar Atena Company manufactures and markets all kinds of steel pipes in different sizes and thicknesses with the most advanced machines in the world and based on international standards. These products range from 6 inches to 16 inches with thicknesses of 4.8 mm 16 mm, which have different applications, including steel water supply and casing pipes.

Casing pipe

The casing pipe is one of the vital components in the oil and gas industry, which plays a very important role in pumping, extracting and transferring fluids. These pipes are placed vertically inside the oil and gas wells and are responsible for protecting the environment around the well and controlling the fluid flow.

Types of casing pipes

The material of the well casing pipes can be made of alloy steel, polyethylene or PVC, which are produced in different shapes and sizes and in regular or slotted form so that can be compatible with the conditions of different wells.

-

Slotted Casing Pipe, which are pipes with slots cut into them in different pattern, is used for pumping and passing water and fluids, especially in the depth of the wells. This pipe acts as a filter to separate the sand in the well during the fluid extraction operation.

-

Casing Pipe is also used to transfer fluids in the depth of wells, which is more resistant to pressure due to the absence of slots cut. This pipe is mainly produced from materials such as PVC, high pressure polyethylene (HPP) or steel.

Application of casing pipe

- Environmental protection: Casing pipe is used as a protective cover so that oil, gas or salt water inside the well does not reach the surrounding environment and prevent external pollution.

- Flow control: Casing pipes help to control the flow of fluids inside the well. They are also used to prevent improper drilling and to balance the pressure inside the well.

- Supporting the structure of the well: Casing pipes acts as an element compatible with the structure of the well and by creating stability in it, prevent the collapse and overflow of soil into the well.

Advantages of using casing pipe

- Resistance to corrosion, rust, pressure and impact

- High strength and durability of pipes

- Saving time and money

- Environmental Protection

- Improving efficiency and safety

specifications of slotted casing pipe

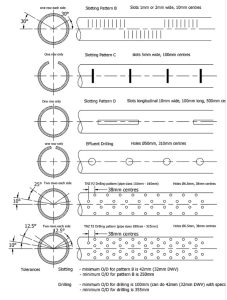

Slotted casing pipes designed for use in the oil industry prevent sand from entering the pipe and reduce oil well maintenance costs. These pipes are mainly made of stainless alloy steel and are usually used with different diameters (between 50 and 500 mm) and different thicknesses (up to 20 mm) and in lengths less than 15 meters. Slots on the surface of the pipe are created to prevent the penetration of sand and facilitate the fluid flow. Usually, the number of cuts, the distance between them and types of this cuts will be different according to the customer’s order and based on the type of drilling, depth and type of passing fluid.

Slot Shapes

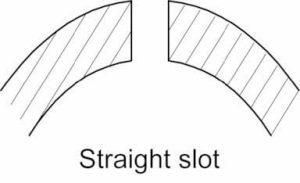

- Straight slots have the same width and are created on the inner and outer surface of the pipe. Straight slots have more wear resistance than sealed keystone slots and are more economical.

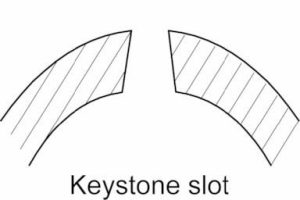

- Keystone slots are like an inverted “V” with a narrower gap on the lining surface and a wider gap on the inner casing wall. This shape allows the sand grains to bridge over the opening, ensuring that all particles entering the hole pass completely through the wall.

Slot patterns

Among all slot patterns, the following three are the most common:

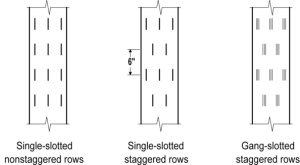

- Line pattern (straight): In line pattern, the slot cuts are evenly spaced in straight lines around the pipe.

- Single staggered slots: The slots are staggered along each other and with the same distance around the pipe.

- Multiple staggered slots: This pattern includes multiple and stepped slots are along each other and placed at the same distance around the pipe. Greater torque tolerance, higher pressure and heat resistance compared to single staggered pattern are the advantages of this slot pattern.

You can see different forms of slots as seen in the photo below

Standards and specifications of steel slotted casing pipe

|

Usually from 50 to 500 mm |

Outside Diameter (OD) |

|

up to 20 mm |

Wall Thickness (WT) |

|

Less than 15 meters |

Length (L) |

|

Depending on the customer’s request |

Number of slots |

|

Depending on the customer’s request |

Slot distance |

|

Depending on the customer’s request |

Slot type |

|

API 5CT، BS EN ISO11960، NFM87-207، JIS G3439، ISO 4270، GOST632-80 |

Standard |

|

Seamless (SMLS)، Electric resistance welding (ERW |

Process method |

|

H40، J55، K55، N80-1، N80Q، R95، L80-1، L80-9Cr، L80-13Cr، C90، T95، C110، P110، Q125 |

Ingredient |

|

STC، LTC، BTC, etc. |

Pipe Covers |

|

Plain, oblique, square cut, miter joint |

Pipe cutting |