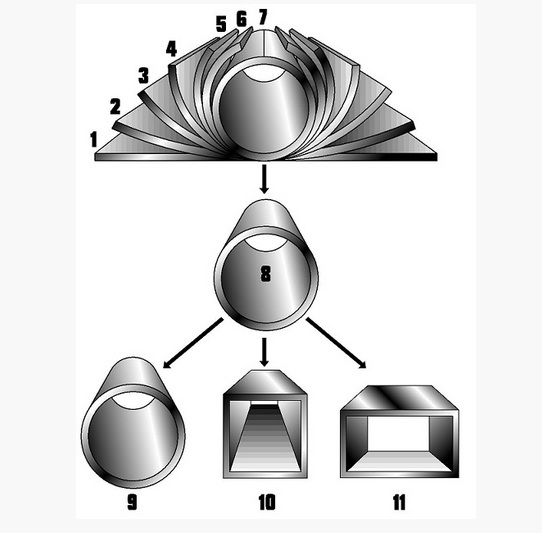

Traditional sections are empty HSS

Many structural engineers know the advantages of HSS in construction, but since the production of these hollow sections in Iran was limited in the past, engineers had no choice but to use sections made with sheets.

Even though traditionally made sections are similar in appearance to HSS sections, the welding process and low quality of their construction greatly affect the final quality of the products. The amount of damage caused by welding and residual stress is less in HSS.